Solution:

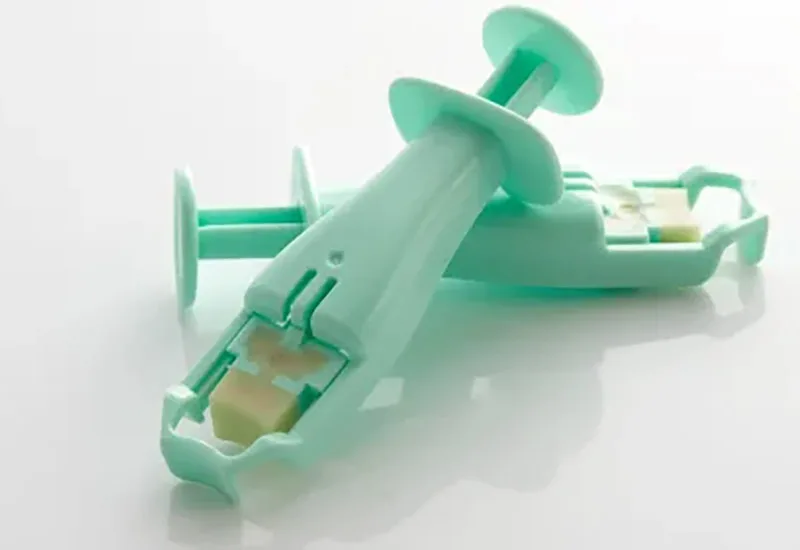

Medical diagnostic equipment components are complex and diverse, with both grooves and protrusions. The outer surface must not have defects such as weld marks, gas marks, or burrs, and has high requirements for brightness.

In the entire injection molding product, customers present product samples and existing components or need to replace existing modules. It is necessary to analyze the structural characteristics of the product and control the deformation of different products through reasonable molding processes to achieve complete matching between different products.

Can provide: 1. Injection molded casing;

Product advantages:

Design capability: Possess the ability to reverse engineer products, provide integrated services including manufacturability assessment, moldflow analysis, mold design, and mold processing and manufacturing;

Manufacturing capability: high-precision injection molding, ensuring accuracy;

Appearance treatment: optional materials, customized services to ensure consistent product appearance;

Durability guarantee: excellent thermal stability and corrosion resistance;